IgGenix, a pioneering biotechnology startup, is dedicated to developing therapeutics for allergic diseases, helping millions of people whose daily lives are limited by food allergies and other severe allergic conditions.

IgGenix harnesses innovative single-cell techniques to isolate immunoglobulin E (IgE)-producing B cells. By engineering the IgE antibodies, which play a pivotal role in triggering allergic reactions, the company transforms them into a potential source for innovative treatments.

While it has been known for decades that IgE mediates allergic reactions by binding food allergens and docking onto surface receptors of histamine-containing cells, it wasn't until 2018 that Dr Croote and colleagues successfully characterized IgE-producing B cells. These cells are extremely rare, which makes studying allergic reactions a complicated task. Using single-cell techniques allows the company to overcome this challenge, recovering the sequences that comprise monoclonal IgE antibodies. Once the sequences are identified, IgGenix can express them and characterize them to understand what allergens they bind and with what affinities. For example, IgE-producing B cells can be isolated from a blood sample of an individual with a peanut allergy, out of which IgGenix can discover and characterize peanut-specific antibodies. These can later be re-engineered to demonstrate their capability to prevent allergic reactions in vivo.

We interview IgGenix Chief Technical Officer, Dr. Derek Croote, who has a lifelong dairy allergy, on his pivotal role as one of the founding members of IgGenix. Here, he shares the strategic decision-making process for selecting Labguru and subsequently overseeing its implementation throughout the organization.

What is your role in IgGenix?

As chief technical officer, I design our computational workflows, perform a variety of data analyses, and manage the lab work. I also have various executive responsibilities involving hiring, budgeting, fundraising, providing scientific updates to our boards, and managing external relationships.

What is the most challenging part of your job?

We’re a small team — 9 people in total — so we’re aggressively pursuing many different projects in parallel. That is both really exciting and challenging in terms of management. That’s where, for me personally, tools like Labguru are crucial for our growth tragegtory as it can provide transparent up-to-the-minute updates on the status of projects.

Using Labguru as a Biotech Start-Up

When did you decide to start using Labguru?

We’ve been using it since we founded IgGenix, 19 months ago.

In my initial exploration of diverse lab notebook solutions, Labguru emerged as the best value. I was particularly impressed by Labguru’s consistent track record of feature growth over time and the full suite of functionalities that spanned an electronic lab notebook (ELN), an informatics software, an inventory system, and more.

How did the implementation process go?

It went very smoothly. Labguru’s interface is very intuitive. The onboarding process is really easy, so I had to spend very little time training employees on the system. The division of the interface into specific components — such as protocols, experiments, papers, inventory, etc — simplifies things and allows new users to begin working quickly.

Would you recommend other biotech startups to implement a lab management software like Labguru from the start?

Absolutely, without a doubt. I think a Lab Management Software like Labguru is crucial for an early-stage biotech company to move forward as quickly as possible. In a startup, where every team member wears multiple hats ,having a robust informatics software not only streamlines processes but also saves valuable time—an indispensable asset for maximizing efficiency and achieving rapid progress.

Has Labguru proved useful to you?

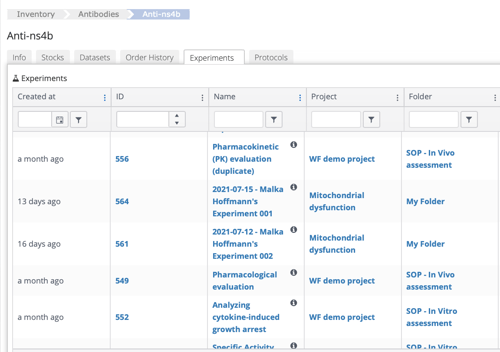

Definitely. We use the ELN extensively and make heavy use of the inventory system as well. The most important feature of Labguru, in my opinion, is the native integration between the ELN and the inventory system where samples can be linked with experiments. We work on antibody discovery and development, and this native integration allows us to look up, in just a few seconds, every experiment where a specific antibody was ever used. That’s really powerful for understanding the unique properties of antibodies we’re discovering for the eventual treatment of allergic diseases.

Crucially, we’ve also found the Labguru support team to be extremely responsive and helpful, the growth in features has been impressive, and I’ve particularly enjoyed implementing several workflows that allow us to automate manual, repetitive tasks.

“The most important feature in Labguru is the native integration between the ELN and the inventory system…It allows us to look up, in just a few seconds, every experiment that a specific antibody was ever used in.”

Automating Routine Data Processing

You often use the Labguru Workflow Editor. Can you share your experience and how you use it?

We use Labguru’s Workflow Editor for routine data processing. This has been really helpful because it allows us to focus on what’s most important: the interpretation of data and the planning of experiments.

One example is the cleaning, reformatting, and plotting of qPCR data automatically when a CSV gets uploaded to an experiment.

The workflow steps look like this:

One of our team members places a 96 or 384 well plate in a qPCR machine. The machine outputs a CSV file. The format of the machine output varies depending on whether it’s a 96 or 384 well plate. In either case, after the run is complete, the research associate or scientist saves the CSV file and uploads it to Labguru.

Instead of manually processing the raw data file from the machine and plotting it, once the file is uploaded to Labguru, the Workflow Editor is activated and does it automatically. Based on the naming convention, the flow recognizes the size of the plate and performs the matching analysis.

The output of the workflow is an interactive visualization of the data, as well as a specific set of wells or conditions that are positive by qPCR. We can then use those results and proceed with downstream steps knowing which wells to focus on.

In the future, I anticipate automating even the data upload part of the process: having the instrument on a secure computer connected to Labguru, and when the file is saved having it automatically uploaded to the relevant experiment in Labguru. This will save even more time for our scientists.

How did you find the process of creating these workflows?

I found Labguru Workflow Editor very easy and intuitive in terms of the design framework. Labguru has great API documentation, so it was quite straightforward to begin creating workflows based on that documentation. After establishing several workflows, I was able to build upon them and automate even more features.

1.png?width=500&height=275&name=Untitled%20design%20(7)1.png)

“Automating data processing with Workflow Editor allows us to focus on what’s most important: the interpretation of data and the planning of experiments.”

Digitizing Inventory Management

You’ve mentioned that you use the inventory module quite extensively. Can you tell me more about how you do that?

If you want to manage a smart laboratory, I believe you should be very meticulous about keeping track of inventory items. In IgGenix, we track the location and quantity of consumables as well as valuable assets such as antibodies. This enables anyone in our team to go on Labguru and find exactly what they’re looking for.

There’s some upfront cost to keeping track of details, but you avoid considerable complexity and confusion down the line, so it’s a worthwhile investment.

Have you used the option to customize your own collections?

Yes, for example, we have a custom inventory collection for the single-cell RNA sequencing plates that we process. This lets us record their unique properties in custom fields. As these plates move through the single-cell RNA sequencing process, we can keep track of them and keep them tied together to our research by adding them to the relevant experiments.

Key Results

Can you describe the ROI that you receive from Labguru?

I can confidently say that tens of thousands of dollars have been saved, especially when you consider the time saved. Time is the most valuable resource for a start-up, and my team is quite small, so any time we can save on routine manual work or research data management is tremendously impactful for our company.

Take the qPCR example, which is only one of the many workflows that I’ve designed. We run hundreds of plates through qPCR every month, and automating the process of cleaning, reformatting, and plotting that data saves about 10-15 minutes per plate.

In total, I think we usually save up to a week per month that would otherwise be wasted on repetitive manual work.

Anything else?

I really enjoy using Labguru. I feel like I have a high bar for recommending new technology, so it means a lot when I say that I’m honestly pleased with it. I am genuinely excited about the prospect of upcoming features and innovations that the Labguru team is contemplating.

To learn more about how Labguru can help you, book a demo:

%20(4).png?height=380&name=NEW%20Featured%20images%20%20-%20Blog%20(1200%20%C3%97%20750%20px)%20(4).png)

.png)

.png)